About Stainless Steel Tubes:

In the realm of industrial applications, the choice of materials is paramount for ensuring reliability, efficiency, and longevity. Among the myriad of options available, stainless steel tubes stand out as a preferred choice for engineers and manufacturers. Renowned for their durability, corrosion resistance, and versatility, stainless steel tubes offer a multitude of benefits that drive success across various industries. In this comprehensive guide, we’ll explore the five key advantages of using stainless steel tubes in industrial applications, shedding light on their indispensable role in shaping modern manufacturing processes.

1. Corrosion Resistance:

One of the most notable benefits of stainless steel tubes is their exceptional corrosion resistance. Unlike traditional carbon steel or other metals, stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing rust and corrosion even in harsh environments. This inherent corrosion resistance makes stainless steel tubes ideal for applications exposed to moisture, chemicals, and corrosive substances, ensuring long-term durability and reliability.

2. High Strength and Durability:

Stainless steel tubes boast impressive strength-to-weight ratios, making them stronger and more durable than many other materials. Whether subjected to high temperatures, heavy loads, or extreme pressures, stainless steel tubes maintain their structural integrity and mechanical properties, minimizing the risk of deformation, cracking, or failure. This inherent strength and durability make stainless steel tubes suitable for demanding industrial applications such as construction, transportation, and heavy machinery.

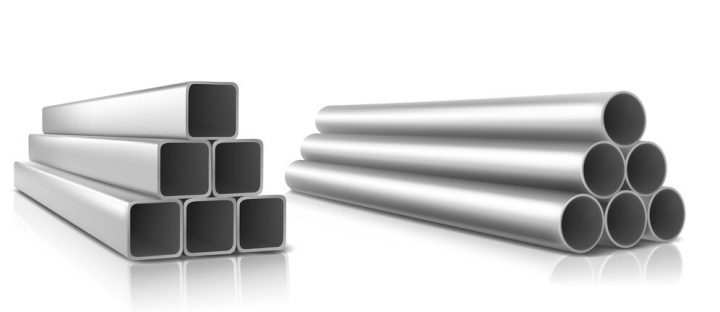

3. Versatility and Adaptability:

Stainless steel tubes offer unparalleled versatility, with a wide range of sizes, shapes, and configurations available to meet diverse application requirements. From round, square, and rectangular profiles to seamless and welded constructions, stainless steel tubes can be tailored to fit specific design criteria and manufacturing processes. This adaptability allows engineers and manufacturers to optimize performance, reduce waste, and achieve precise dimensions, enhancing overall efficiency and cost-effectiveness.

4. Hygienic Properties:

In industries such as food and beverage, pharmaceuticals, and healthcare, maintaining hygiene and cleanliness is paramount. Stainless steel tubes are inherently hygienic, thanks to their smooth, non-porous surfaces that resist bacterial growth and contamination. Unlike materials with rough or irregular surfaces, stainless steel tubes are easy to clean, sterilize, and maintain, ensuring the integrity and purity of sensitive processes and products. This makes stainless steel tubes the preferred choice for critical applications where sanitation is essential.

5. Sustainability and Environmental Benefits:

Stainless steel tubes offer significant environmental benefits compared to other materials, thanks to their recyclability, longevity, and low environmental impact. Stainless steel is 100% recyclable, with scrap materials being readily melted down and reused to produce new stainless steel products. Additionally, stainless steel tubes have a long service life and require minimal maintenance, reducing the need for replacements and conserving resources over time. By choosing stainless steel tubes, industries can minimize their environmental footprint and contribute to a more sustainable future.

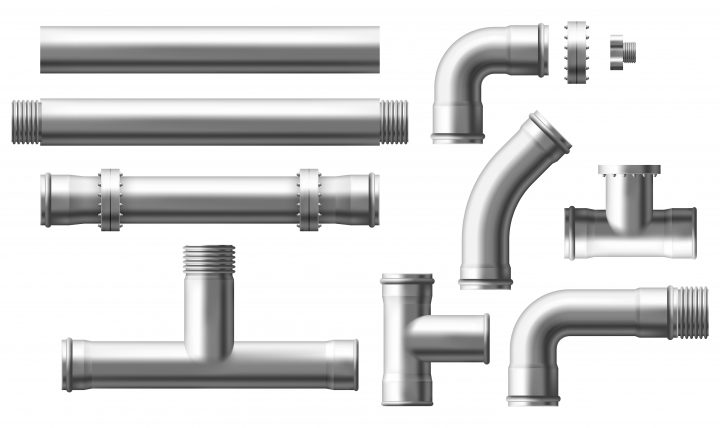

Conclusion:

Stainless steel tubes stand as indispensable components in industrial applications, offering a winning combination of corrosion resistance, strength, versatility, hygiene, and sustainability. From structural supports and fluid conveyance systems to architectural elements and medical devices, stainless steel tubes play a vital role in shaping modern manufacturing processes and infrastructure.

By harnessing the key benefits of stainless steel tubes, industries can achieve greater reliability, efficiency, and longevity in their operations, driving success and innovation across diverse sectors. With their unmatched performance and versatility, stainless steel tubes are poised to remain a cornerstone of industrial excellence for years to come.

Moreover, for sourcing top-quality stainless steel tubes and related products, look no further than Enggpro. Enggpro serves as a comprehensive platform connecting buyers with leading manufacturers and suppliers of stainless steel tubes, ensuring seamless procurement processes and access to a wide range of products. Explore Enggpro today to unlock a world of possibilities in stainless steel tube procurement and elevate your projects to new heights of excellence.