Understanding Mechanical Coupling:

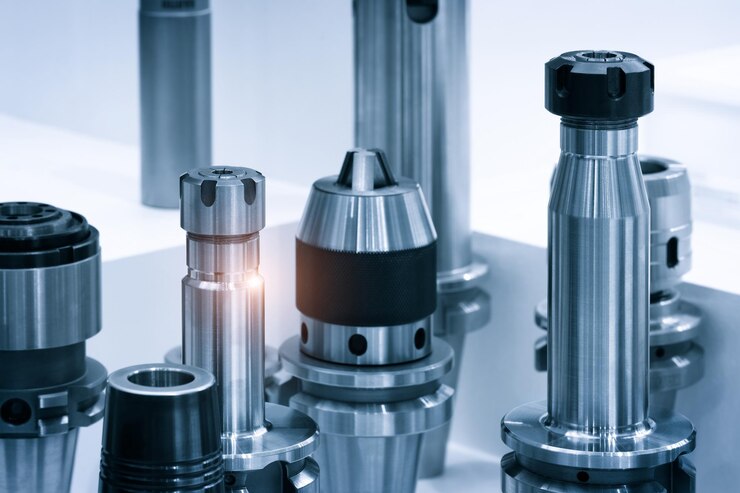

In the world of machinery and equipment, mechanical couplings play a crucial role in transmitting torque and motion between rotating shafts. They provide a vital connection that allows the transfer of power and rotational movement from one component to another. In this blog post, we will delve into the concept of mechanical coupling, explore different types of couplings, and discuss their applications. Additionally, we will highlight the importance of reliable coupling manufacturers and suppliers in ensuring optimal performance and efficiency.

Mechanical coupling refers to the mechanism used to connect two shafts, enabling the transmission of rotational power and torque between them. Couplings compensate for misalignment, vibration, and shock loads while maintaining a strong connection. They also facilitate disconnection for maintenance or replacement of components without disassembling the entire system. By providing a reliable link, mechanical couplings enhance the overall functionality and performance of machinery.

Types of Mechanical Couplings:

1. Flexible Couplings:

– Jaw Couplings: Commonly used in general-purpose applications, jaw couplings provide flexibility and dampen vibrations.

– Gear Couplings: Ideal for high torque applications, gear couplings offer exceptional misalignment compensation and torque transmission capabilities.

– Diaphragm Couplings: Known for their high torque capacity, diaphragm couplings are suitable for precision positioning and low backlash requirements.

– Disc Couplings: Designed for high-speed applications, disc couplings provide torsional stiffness and excellent misalignment compensation.

2. Rigid Couplings:

– Sleeve Couplings: Also known as rigid couplings, sleeve couplings provide a solid connection and precise alignment between shafts.

– Clamp Couplings: Featuring a split design with clamping screws, clamp couplings offer ease of installation and secure shaft connections.

3. Fluid Couplings:

– Hydraulic Couplings: Utilizing hydraulic fluid, hydraulic couplings transmit torque and provide overload protection in heavy-duty applications.

– Pneumatic Couplings: Employing compressed air, pneumatic couplings offer torque transmission and rapid disconnection capabilities.

Applications of Mechanical Couplings:

Mechanical couplings find applications in various industries and machinery, including:

– Power transmission systems in manufacturing plants and industrial equipment.

– Conveyor systems for material handling in warehouses, mining, and agriculture.

– Pumping systems in water treatment plants, oil and gas industries, and chemical processes.

– Automotive drivetrains for connecting engine components to wheels.

– Aerospace and aviation systems for transmitting power in engines and turbines.

– Wind turbines for transferring rotational energy from the blades to the generator.

The Role of Reliable Coupling Manufacturers and Suppliers:

To ensure the efficiency and performance of mechanical couplings, it is essential to partner with reputable coupling manufacturers and suppliers. They offer several benefits, including:

– High-quality Products: Established manufacturers and suppliers produce couplings that meet industry standards, ensuring durability and reliability.

– Expertise and Support: Manufacturers provide technical expertise, guidance, and support during the selection and installation process, optimizing coupling performance.

– Customization: Reliable manufacturers and suppliers offer customized solutions to meet specific application requirements, ensuring an optimal fit for the machinery.

– Timely Delivery: Efficient suppliers have streamlined processes to ensure timely delivery of couplings, minimizing downtime for the machinery.

Conclusion:

Mechanical coupling is a fundamental aspect of engineering, providing a means to connect and transmit motion, torque, and power between rotating components. With various types of couplings available, engineers can select the most suitable coupling for their specific applications, considering factors such as torque requirements, misalignment, and environmental conditions. The versatility of mechanical couplings has enabled their widespread adoption across multiple industries, contributing to the efficient and reliable operation of machinery and systems worldwide.

For engineers and businesses seeking coupling manufacturers and suppliers, Enggpro is a valuable resource. Enggpro is a leading B2B marketplace for engineering products and services, connecting buyers and sellers in the engineering industry. Whether you are looking for specific types of couplings or other engineering components, provides a platform to discover reputable manufacturers and suppliers, facilitating efficient procurement processes and ensuring high-quality products. Visit our platform today to explore a wide range of engineering solutions and connect with trusted suppliers.