Item

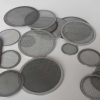

Metal filters

Category

Metals

Code

-

Moc

-

Stock Location

-

Dimension

-

Stock

-

Created On

01/08/2023

Updated On

01/08/2023

filter element manufacturer,as the demand for filtration systems continues to rise, so does the need for high-quality filter elements. A filter element plays a crucial role in ensuring the efficiency and effectiveness of a filtration system by removing impurities, contaminants, and unwanted particles from fluids or gases. As a result, filter element manufacturers have become essential players in various industries, including automotive, aerospace, oil and gas, pharmaceutical, and manufacturing.

The manufacturing process for filter elements involves several steps, including material selection, design, production, and quality control. Here, we will explore the process involved in manufacturing filter elements, as well as the challenges and opportunities faced by filter element manufacturers.

Material Selection

The first step in manufacturing filter elements is selecting the appropriate materials. The criteria for material selection depend on the specific application and the type of filtration required. Common materials used for filter elements include metals, such as stainless steel or brass, and synthetic materials, such as polyester, polypropylene, or polyethylene. The choice of material depends on factors such as temperature resistance, chemical compatibility, and mechanical strength.

Design

Once the material is selected, the next step is designing the filter element. This involves determining the shape, size, and configuration of the filter element, as well as the type of filtration media and the construction method. The design process takes into account factors such as filtration efficiency, flow rate, pressure drop, and operating conditions. The design must also comply with industry standards and regulations.

Production

With the design finalized, the production of filter elements can begin. The production process typically involves several steps, including cutting, shaping, welding, and assembly. The manufacturing equipment used may vary depending on the complexity of the design. For example, simple filter elements may be produced using manual processes, while more complex designs may require automated machinery.

Cutting and Shaping

The first step in production is cutting and shaping the selected material. This may involve using cutting tools, such as lasers, water jets, or stamping machines, to cut the material into the desired shape and size. The material may also undergo additional shaping processes, such as bending, rolling, or molding, to achieve the required geometry.

-