Introduction:

In the realm of plumbing, construction, and industrial engineering, pipe fittings are the unsung heroes that ensure seamless connectivity and functionality within piping systems. From simple residential plumbing setups to complex industrial networks, understanding the various types of pipe fittings is crucial for engineers, technicians, and DIY enthusiasts alike. In this comprehensive guide, we’ll delve into the world of pipe fittings, exploring their types, functions, and applications to equip you with the knowledge needed to navigate the intricate world of piping systems.

What are Pipe Fittings?

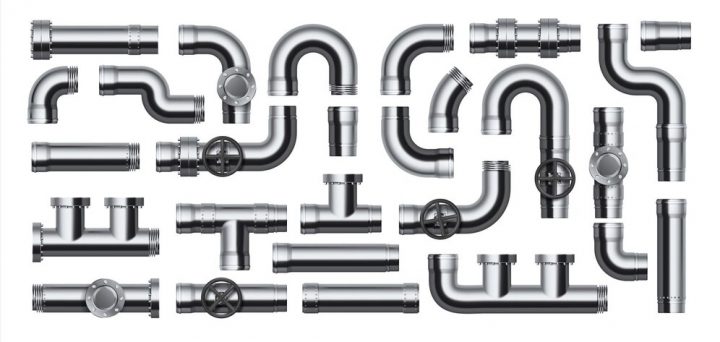

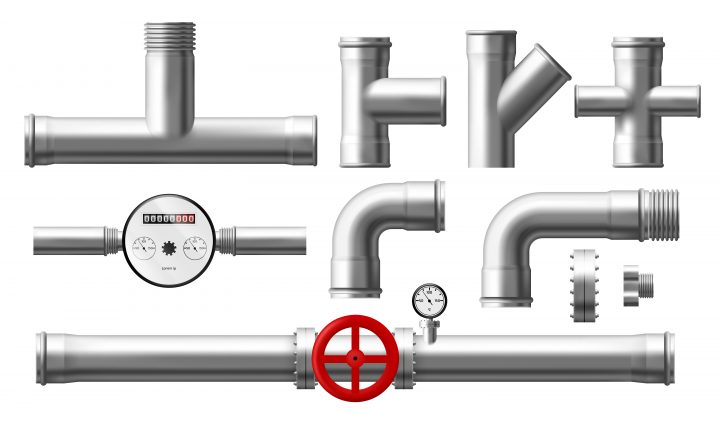

Pipe fittings are components used to connect, redirect, or terminate the flow of fluids (liquids or gases) within piping systems. They come in a plethora of shapes, sizes, and materials, each serving specific functions depending on the requirements of the application. Whether it’s joining pipes of different sizes, changing the direction of flow, or regulating fluid pressure, pipe fittings play a vital role in ensuring the efficiency and reliability of piping systems.

Types of Pipe Fittings:

1. Couplings:

– Couplings are used to join two pipes of the same diameter together. They come in various forms such as compression couplings, slip couplings, and threaded couplings.

– Commonly used in residential and commercial plumbing for straightforward pipe connections.

2. Elbows:

– Elbows are fittings that enable changes in the direction of piping systems. They are available in different angles, typically 45 degrees and 90 degrees, to accommodate various layout requirements.

– Widely used in HVAC systems, water distribution networks, and industrial pipelines.

3. Tees:

– Tees allow the branching of piping systems into two or more directions. They feature a T-shaped design with an inlet and two or more outlets.

– Essential components in plumbing systems, irrigation networks, and process piping applications.

4. Reducers:

– Reducers are fittings used to connect pipes of different diameters. They come in two types: concentric reducers (maintaining a straight axis) and eccentric reducers (offsetting the centerline).

– Found in applications where fluid flow needs to be transitioned from one size to another, such as pump discharge lines and pipeline expansions.

5. Caps:

– Caps, also known as end caps or plugs, are fittings used to seal the end of a pipe. They prevent the leakage of fluids and debris ingress, ensuring system integrity.

– Employed in both pressurized and non-pressurized systems, including water supply lines, gas pipelines, and drainage systems.

Applications of Pipe Fittings:

1. Plumbing Systems:

– Pipe fittings are integral to residential, commercial, and industrial plumbing systems, facilitating the distribution of water, gas, and sewage.

– They ensure proper connectivity and functionality of fixtures, faucets, and appliances, contributing to the comfort and safety of occupants.

2. HVAC (Heating, Ventilation, and Air Conditioning):

– HVAC systems rely on pipe fittings for fluid circulation, heat transfer, and air distribution.

– Fittings such as elbows, tees, and reducers play a crucial role in routing hot and cold water, refrigerants, and ventilation ducts throughout buildings.

3. Industrial Processes:

– In industrial settings, pipe fittings are used in a myriad of applications including chemical processing, oil & gas production, and manufacturing.

– They facilitate the transport of raw materials, fluids, and byproducts, ensuring the efficiency and safety of production processes.

4. Fire Protection Systems:

– Pipe fittings are essential components of fire sprinkler systems and firefighting networks.

– They enable the rapid delivery of water to extinguish fires, safeguarding lives and property in residential, commercial, and industrial settings.

Conclusion:

Pipe fittings are the backbone of piping systems, enabling the seamless flow of fluids in various applications ranging from residential plumbing to industrial processes. By understanding the different types of pipe fittings and their respective functions, engineers, technicians, and DIY enthusiasts can effectively design, install, and maintain piping systems with confidence and precision. Whether it’s a simple household repair or a large-scale industrial project, mastering the art of pipe fittings is essential for ensuring the efficiency, reliability, and safety of fluid conveyance systems.

Moreover, for sourcing high-quality pipe fittings and related products, look no further than Enggpro. Enggpro serves as a comprehensive platform connecting buyers with top pipe fitting manufacturers and suppliers, ensuring a seamless procurement experience. With Enggpro’s extensive network, businesses can access a wide range of pipe fittings, tailored to their specific requirements, thereby streamlining project execution and enhancing operational efficiency. Explore Enggpro today to unlock a world of possibilities in pipe fitting procurement and elevate your piping system to new heights of excellence.