About Pipe Fittings

In the intricate infrastructure of industries, pipe fittings play a vital role, connecting pipelines and ensuring seamless flow of fluids or gases. India, with its burgeoning industrial landscape, has witnessed a significant rise in the demand for pipe fittings across various sectors. This blog delves into the growth trajectory of pipe fittings manufacturers in India, exploring the factors driving their ascent, the opportunities that lie ahead, and the challenges they face.

The Dynamics of India’s Industrial Expansion

India’s industrial expansion has been fueled by a combination of factors including rapid urbanization, infrastructural development, and government initiatives such as “Make in India” aimed at promoting indigenous manufacturing. Industries such as oil and gas, petrochemicals, water treatment, construction, and agriculture heavily rely on efficient piping systems, thereby driving the demand for pipe fittings.

Key Drivers Behind the Rise of Pipe Fittings Manufacturers

1. Infrastructure Development: The government’s focus on infrastructure development projects such as highways, airports, ports, and smart cities has led to a surge in demand for pipe fittings for water supply, drainage systems, and utility pipelines.

2. Industrial Growth: India’s expanding industrial base, particularly in sectors like oil and gas, chemicals, power generation, and pharmaceuticals, has bolstered the demand for pipe fittings for conveying fluids, gases, and chemicals in manufacturing processes.

3. Urbanization and Real Estate Boom: Rapid urbanization and the burgeoning real estate sector have created a substantial market for pipe fittings in residential, commercial, and industrial construction projects, including plumbing and HVAC systems.

4. Technological Advancements: Technological advancements in manufacturing processes, such as CNC machining, automation, and 3D printing, have enabled pipe fittings manufacturers to enhance production efficiency, improve product quality, and meet custom requirements.

5. Quality Standards and Certification: Increasing awareness about the importance of quality and safety standards has prompted pipe fittings manufacturers to adhere to international quality certifications such as ISO, ASTM, ASME, and API, enhancing their credibility and competitiveness in the global market.

Opportunities in the Pipe Fittings Manufacturing Sector

1. Export Potential: With India emerging as a manufacturing hub for various industries, there is immense export potential for pipe fittings manufacturers to tap into international markets. Strategic partnerships, trade agreements, and compliance with global standards can open doors to lucrative export opportunities.

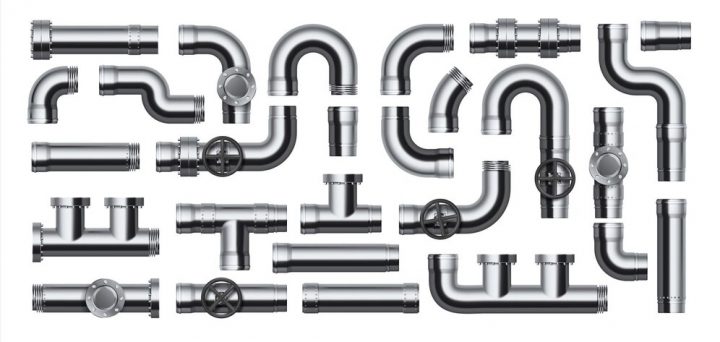

2. Diversification of Product Portfolio: Pipe fittings manufacturers can explore diversification by expanding their product portfolio to include a wide range of fittings such as elbows, tees, couplings, valves, and flanges, catering to diverse applications and industries.

3. Investment in Research and Development: Investing in research and development (R&D) initiatives to innovate new products, improve existing designs, and enhance manufacturing processes can give manufacturers a competitive edge in terms of product differentiation and market positioning.

4. Focus on Sustainability: With growing environmental concerns, there is a shift towards sustainable manufacturing practices and eco-friendly materials. Pipe fittings manufacturers can capitalize on this trend by offering environmentally friendly products and adopting green manufacturing processes.

5. Digital Transformation: Embracing digital technologies such as IoT, automation, and predictive analytics can revolutionize the pipe fittings manufacturing sector, enabling real-time monitoring of production processes, predictive maintenance, and optimization of supply chain management.

Challenges Facing Pipe Fittings Manufacturers

1. Competition from Low-Cost Imports: Pipe fittings manufacturers in India face stiff competition from low-cost imports, particularly from countries with lower production costs. To compete effectively, manufacturers need to focus on cost optimization, quality assurance, and value-added services.

2. Supply Chain Disruptions: Disruptions in the global supply chain, whether due to geopolitical tensions, natural disasters, or pandemics like COVID-19, can impact the availability of raw materials, components, and logistics, posing challenges for timely production and delivery.

3. Skilled Labor Shortage: The shortage of skilled labor, particularly in specialized fields such as CNC machining, welding, and quality control, poses a significant challenge for pipe fittings manufacturers. Investing in training and development programs is essential to address this skill gap.

4. Regulatory Compliance: Compliance with regulatory requirements and standards, both domestic and international, adds complexity to the manufacturing process and increases compliance costs. Manufacturers need to stay updated on regulatory changes and invest in quality management systems to ensure compliance.

5. Price Volatility of Raw Materials: Fluctuations in the prices of raw materials such as steel, copper, and PVC, which are primary materials used in pipe fittings manufacturing, can impact production costs and profit margins. Effective supply chain management and hedging strategies are essential to mitigate price risks.

Conclusion

The rise of pipe fittings manufacturers in India signifies the country’s growing prowess in the manufacturing sector and its ability to cater to diverse domestic and international markets. With robust growth drivers such as infrastructure development, industrial expansion, and technological advancements, the future looks promising for pipe fittings manufacturers. However, addressing challenges such as competition, supply chain disruptions, and regulatory compliance requires proactive strategies and continuous innovation. By capitalizing on opportunities, investing in technology and talent, and maintaining a customer-centric approach, pipe fittings manufacturers can navigate the complexities of the market landscape and achieve sustainable growth in the dynamic Indian industrial ecosystem. For businesses looking to connect with reputable pipe fitting manufacturers and suppliers, Enggpro offers a comprehensive platform. Explore Enggpro’s extensive list of pipe fitting manufacturers and suppliers to streamline your procurement processes and forge valuable partnerships in the thriving Indian market.